End to End Services

Over the last three decades, we have developed a skilled team to cover the complete spectrum of services our clients need to bring their products to market. By building on our own strengths and developing long-standing relationships for capital intensive processes, we’ve created a dedicated group that works together seamlessly for the most economical and efficient path to success.

Conceptual Design

- Award winning designs (Red Dot, IDEA, DEmark, iF pda …)

- Brainstorming & product ideation

- Preliminary sketches

- Renderings, logics and storyboards

- ID, mechanical, electrical, software and UI concepts

- Class A surfaces for ME templates

- Visual aids, models mockups, material samples & conceptual prototypes

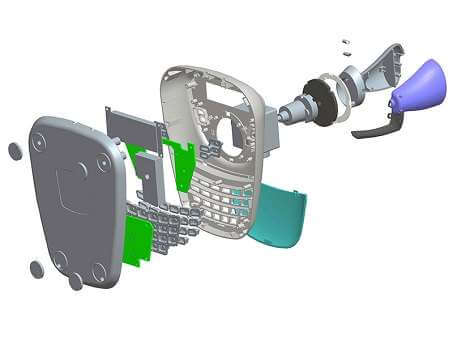

Mechanical Engineering

- Innovative designs that bridge concept to manufacturing

- Cost efficient, manufactureable designs

- Intellectual property transferrable to the customer

- Complete 3D solid models of all components

- Full product documentation and legacy support.

- Range of analysis including FEA and MFA.

Electrical Engineering

- Embedded hardware and firmware design

- Develop custom circuitry or adapt your existing designs

- Full Gerber files and BOMs ready for manufacturing

- Extensive IoT experience

- Support for a broad range of software libraries

- Custom device drivers

Software/UI Design

- Embedded, desktop and handheld

- Bare metal apps to full-featured Real Time Operating Systems (RTOS) or Linux

- Emphasis on UI/UX with feedback research loop

- Web and handheld apps including integrated web database architecture

- Support for all modern libraries/platforms

Packaging Design

- Innovative designs for product packaging and display

- Brand and packaging continuity

- High-quality, cost-efficient designs

- Material selection

- Print-ready deliverables

- Direct interface to packaging suppliers

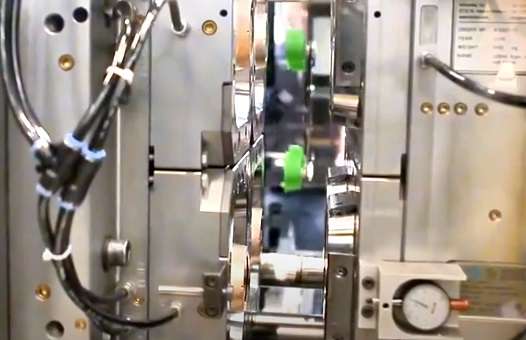

Injection Molding

- ISO 9001, 13485, 14001 and 16949 certified facilities

- ISO Class 7 & 8 clean room molding

- SQF (Safe Quality Food) certified facilities

- Scientific molding procedures for consistency

- Modern, closed-loop, computer controlled equipment

- Presses ranging from 10 to 2,550 tons

- Low-volume (<10K) to ultra-high (>10MM) annual volume molding

- On-site or near final assembly facility

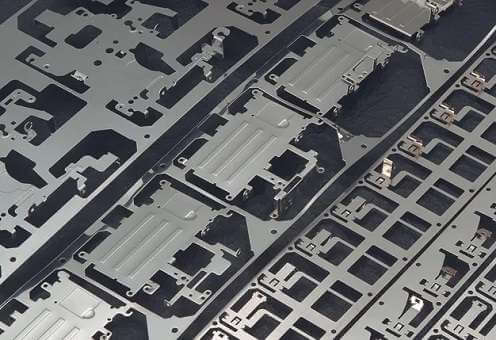

Metal Fabrication

- Progressive die and transfer press stamping

- Broad range of materials including copper alloys for custom contacts

- Complete array of secondary operations

- Hardware insertion and assembly

- Finishing options including plating and powder coating

- Passivation and sterilization

- On-site or near final assembly facility

Casting & CNC Machining

- ISO 9001 and 16949 certified facilities

- Aluminum, zinc and magnesium materials

- Hot and cold chamber die casting

- Investment and sand casting

- CNC machining, drilling, reaming and tapping

- Broad range of finishes/plating

- Presses up to 350 tons

- Near final assembly facility

Project Management

- Dedicated project manager (PM) for each customer

- Transparent top-level scheduling visibility with regular update intervals

- Purchasing and component management reports directly to team PM

- All departmental leads report real-time to PM for top-level roll up

- PM maintains continuity and ownership throughout project

- Custom reports and update intervals per request

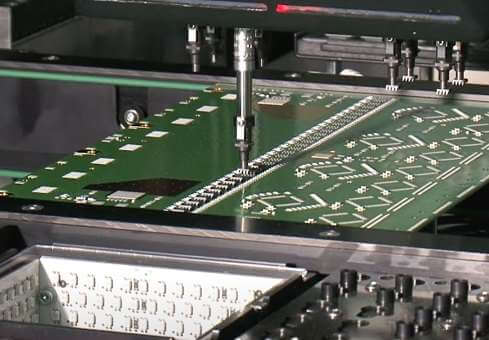

PCB Assemblies (PCBA)

- ISO 9001, 13485 and 14001 certified facilities

- Fully automated SMT (Surface Mount technology)

- Through-hole with wave solder cells and lines

- Flexible modular cell production systems for fast turn around and prototype

- Inline Integrated QMS and component testing

- Inline programming and testing capabilities

- On-site at final assembly facilities

Final Assembly & Testing

- ISO 9001, 13485, 14001 and 16949 certified facilities

- Clean room and SQF (Safe Quality Food) facility options

- Automated lines for high volume manufacturing

- Cell-based lines for low-to-medium manufacturing volumes

- Custom programming, serialization and testing procedures

- Integrated QMS and tracking

Logistics

- Competitive ocean, air and ground contract rates

- Dedicated US import bonds in place

- Maritime cargo insurance

- US Harmonized Tariff Schedule compliance

- Tracking and reporting

- Contract warehousing

Are You Ready?

Ready to accelerate your product development, leverage our production capabilities and tap into decades of contract manufacturing experience? With over 30 years of successfully bringing products to market, you can count on us for on-time, on-budget deliveries. Join small and large companies alike who have trusted us to deliver innovative solutions to complex problems.